A lil' history ...

A lil' history ...

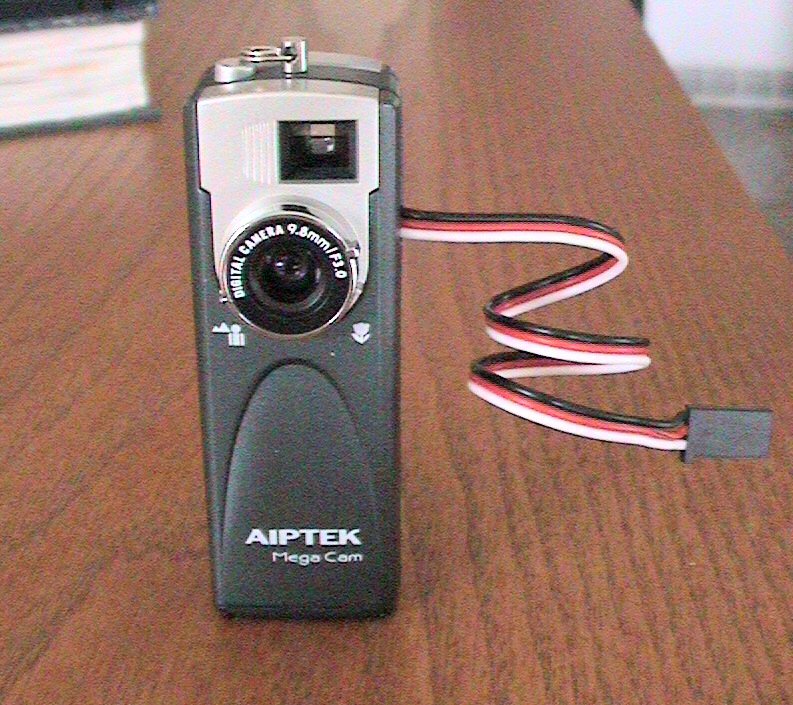

Over a year ago, I

acquired a small miniature digital camera, mainly the

Aiptek 1.3 mega pixel camera. These can still be bought in local

stores such as

Circuit City and other major department stores for $40 or less.

Actually, over the years, I acquired around 8 of these cameras on

Ebay, and if you look long enough and are very patient, you can have one for

under $20 delivered, if not less.

I have received numerous emails from friends and other electronic enthusiasts

regarding the modification of this digital camera for aerial photography use

along with an R/C airplane (preferably electric due to the excessive vibration

of gas-powered planes). One of the easiest methods of modifying the camera

is to simply use an extra servo attached (double-sided tape or even glued) to

the top of the camera, just above the shutter button. This method of orienting the

servo and servo arm such that the servo arm presses the shutter button is

practical but not "clean". It can often be clumsy and can

often malfunction (I have fixed many cameras where the servo arm actually broke

the shutter switch, breaking it from the circuit board, rendering the camera useless).

Another method is to design a simple

electronic circuit that would interface with your R/C receiver and Aiptek

camera. A

simple R/C electronic switch can then be used to remotely trigger the

camera's shutter switch using a spare R/C receiver channel. What would

really be nice though is to have this circuit completely enclosed in the Aiptek

camera, where the only thing exiting the camera would be the servo wire that you

would then

connect to the R/C receiver. Although this might sound easy, the Aiptek

1.3M camera in itself is small. The circuit would therefore have to be

made really small in order to fit comfortably in the Aiptek case. Some

have even designed a neat 8-pin PIC

circuit that is programmed to interface with the receiver servo signal and

the camera's shutter switch. All of the PIC circuit components fit inside the camera case.

Although this might seems like a great idea, even some electronic enthusiasts

tend to shy away from programming PICs. Additionally, PIC circuits (i.e.

oscillators) can generate unwanted EMI, which receivers certainly do not like.

I found this out the hard way a few years back while experimenting.

I therefore wanted to design a simple R/C switch for triggering the Aiptek

shutter switch using ordinary components you can buy at your local electronic

store (i.e. Radio Shack). Also, in order to save weight, I wanted to

design it such that the camera would be powered from the connector going to the

R/C receiver. Most R/C receivers are powered from a battery source which

is typically 4 or 5 cells (4.8v - 6 v). On some electric R/C airplanes,

receivers are typically powered from electronic speed controllers (ESC) which

usually contain a battery elimination circuit (BEC). In either case, this

receiver voltage could be tapped in order to power the camera. Although

the Aiptek camera uses two (2) AA batteries (3 volts), the camera can also be

powered from the Universal Serial Bus (USB) connector. Powering the camera

with batteries works well but if you do not take a picture after a short time,

the camera will automatically shut itself down, requiring you to reactivate

(tough to do when it is in the air). I therefore decided to design the

circuit such that it is powered from the USB connector (the Aiptek camera stays on as long as it is powered

via the

USB connector).

Another design criteria I

wanted is the ability to use the camera "stand-alone", that is, I wanted to be

able to simply pull the camera off my plane, stick a couple of batteries in it

and still be able to take pictures manually.

Design Criteria Summary:

1) Power camera using R/C receiver power

2) Trigger camera shutter switch using spare R/C receiver servo channel

3) Allow use of batteries and allow full, manual operation of camera

4) Design circuit using ordinary parts (i.e. no PICs/programmer or special ICs)

5) Circuit must fit inside existing camera case

OK,... so here we go...... (glad you made it this far.....)

Parts & Tools List

...

1) Aiptek 1.3 mega -pixel

camera

2) 4013 Dual D flip-flop Integrated Circuit (DIP) (Click

here for Datasheet)

3) 22nF (.022uF) Capacitor (the smaller, the better)

4) Two - 100K resistor (again, the smaller, the better.

One might have to be a SMD version)

5) 1N4148 Diode

6) Tiny (28+ gauge?) hookup wires

7) Razor blade or file for trimming case for servo wire

8) Servo hookup wire (w/ male end for connecting to R/C receiver)

9) Soldering iron (1/16" tip) + solder

10) Snippers, pliers, tiny Philips screwdriver, Magnifying glass (if your eyes

are not up to par), etc...

11) Patience! (most important!)

That's it!

If it does not sound like a lot, it isn't! Probably less than $4 worth of

parts.

Building Instructions...

This simple circuit is based upon the

4013 dual D flip-flop

IC and requires only 4 additional passive components (1 cap,

2 resistor and 1

diode). If you want to read about how the circuit actually

operates, see Ken Hewitt's

webpage (the original designer of the circuit). The value of this resistor was chosen such that the "switch

toggle" occurs roughly around the center position of the transmitter stick

(~1.5ms).

This will also allow you to toggle the switch output using a switch on your

transmitter. Depending of your setup (and whether your transmitter allows

you to reverse servo directions), you can either use pin 12 or 13 on the IC (one

is inverse of the other). A diode is also used to interface to the

camera's shutter switch (it acts as a one way "valve", allowing the R/C switch

to control the shutter, while still allowing full manual operation of the

shutter switch. A 100K pull-down resistor was also

added to the servo input lead and ground so as to not allow the input to float

when unplugged from the R/C receiver.

On

the left is a circuit schematic for the R/C

switch.

On

the left is a circuit schematic for the R/C

switch.

The toughest part of this whole project is assembling the R/C

switch

circuit. The idea is to make it as small and compact as possible.

The smaller, the better. The following pictures and text will guide you

through every step of this process.

We'll first open up the camera and make the necessary

modifications/wiring before building the switch circuit.

Open

the battery compartment door slightly until you can see the

retaining screw and remove with a small

Philips screwdriver (a magnetized one will save you lots of trouble (such as

loosing the tiny irreplaceable screw). Once this screw is removed, the top

case section can usually be removed from the camera by gently running your

finger nail along the seam. It might take a bit of fussing but for the

most part, it comes off in a "snap".

Open

the battery compartment door slightly until you can see the

retaining screw and remove with a small

Philips screwdriver (a magnetized one will save you lots of trouble (such as

loosing the tiny irreplaceable screw). Once this screw is removed, the top

case section can usually be removed from the camera by gently running your

finger nail along the seam. It might take a bit of fussing but for the

most part, it comes off in a "snap".

NOTE: Before removing the top case section, adjust

the lens focus such that it is set for infinity (clockwise). Remember this

as when you replace the top case section, you can be assured that the focus

setting is retained. Also, once the top case section is removed, be sure

not to touch the focus lens. Doing so will alter the correct focus and

will require unnecessary refocusing.

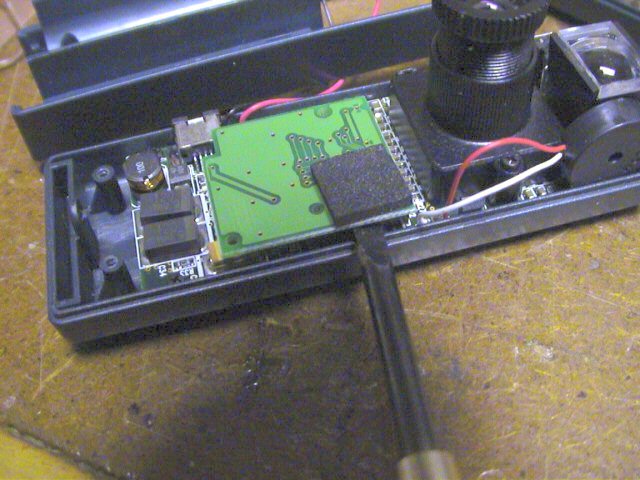

Next, using a small Philips screw driver,

remove the two screws attaching the

middle case section to the bottom case section. Again, be careful not to

loose these screws (I use a magnet attached to my workbench to retain these tiny

screws.... never lost one since).

Once these screws are removed, you should be able to

detach the middle case section from

the lower case section. Be careful not to break any of the attached

battery wires. Simply rotate the middle case section and lay it along side

the bottom case section.

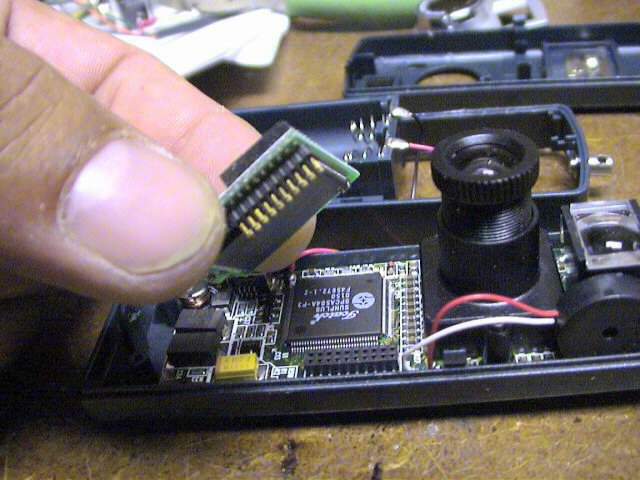

With the middle case section removed, locate the removable memory

card. I used a small plain screw driver to

gently pry the board up from its socket.

You can also gently grasp the board with your fingers and rock it back and forth

to remove.

NOTE: BE VERY CAREFUL IN REMOVING THIS AS "STATIC

ELECTRICITY" WILL RENDER YOU CAMERA USELESS !!. Ground yourself or better

yet, use a grounded ESD strap.

Once pried, gently remove

the memory board and place it in a safe non-static location (preferably a

anti-static bag). Without this daughterboard, you camera is useless.

Removing this memory board will gain you clear access to the USB connector.

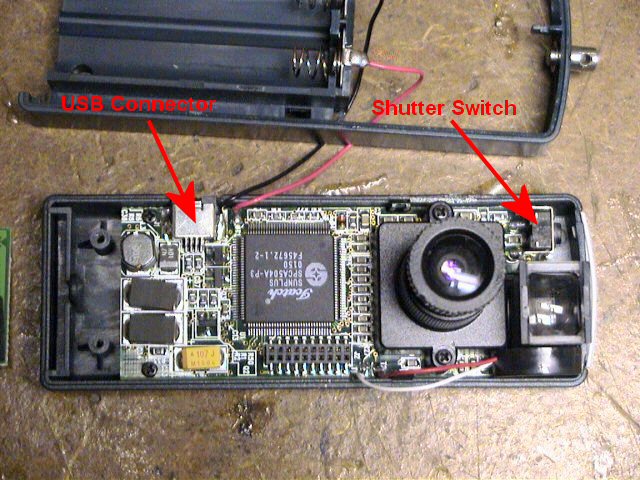

The picture to the left indicates

the location of the USB connector and the

camera's shutter switch connections. The shutter switch has two

connections, one to ground and one to the camera processor. We only need

to make a connection to the switch pin that is connected to the processor (the

pin closest to the outside of the camera).

Using

a small piece of insulated wire and a small tipped soldering iron,

solder the wire to the switch connection

as shown. After soldering, you can test the connection by temporarily

installing the batteries, waiting for the camera to beep (powered and ready) and

then touching this wire to ground (the metal case part of the switch is fine).

If properly connected, this should force the camera to take a picture and beep.

Using

a small piece of insulated wire and a small tipped soldering iron,

solder the wire to the switch connection

as shown. After soldering, you can test the connection by temporarily

installing the batteries, waiting for the camera to beep (powered and ready) and

then touching this wire to ground (the metal case part of the switch is fine).

If properly connected, this should force the camera to take a picture and beep.

NOTE: To properly test, you will need to temporarily

reinstall the memory board first.

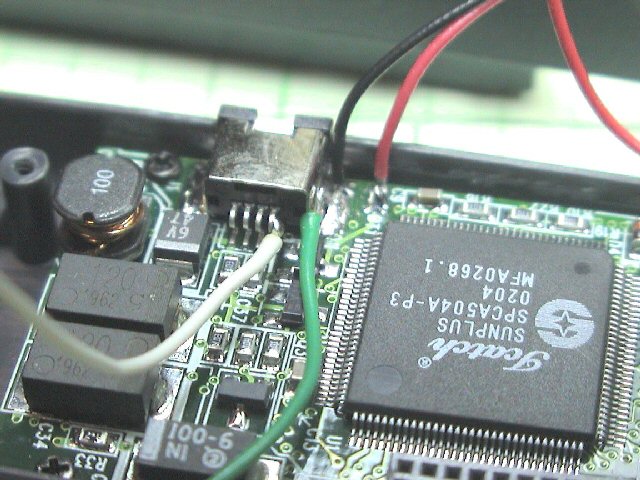

Next, connect two pieces of

wire to the USB connector. One wire will connect to ground (the metal

casing of the USB connector). The other connection can be a little tricky.

You need to make a connection to the outside pin (#1) of the USB connector.

You need to be VERY CAREFUL in making this connection as again, it can render

your camera useless. Such that you have adequate space, make the

connection to the USB pin first (then connect USB ground connection).

First, tin the end of your insulated wire and trim it such that the exposed

tinned wire is approximately 1/16". You can also dab a little flux onto

the USB pin prior to soldering. This will help facilitate the quick

soldering of the wire. Touch the tinned wire to the outside of the USB

pin, then gently apply your soldering iron to the tinned wire.

NOTE: DO NOT APPLY TOO MUCH PRESSURE TO THE WIRE/USB

CONNECTOR ! Doing so will most likely break the connection from the USB pin

to the camera board and you will then be unable to use the USB connector for

downloading pictures. Trust me,,, I have done this..... ONCE!.

Apply enough heat to the wire such the it gently connects to the

USB lead. After making this connection, you can again test the camera to

be assured it is still working properly (you might want to also check the USB

connector by attaching it to your PC and downloading pictures).

NOTE: To properly test, you will need to temporarily

reinstall the memory board first.

After being assured that it is connected and the camera is still

functional, make the ground connection to the USB metal case (you might have to

use some additional heat to get it to connect)... phew..... the tough part is

now done!

I usually then apply some

hot melt glue (or such) to the USB connection just to be certain that

excessive vibration does not bother the connection. I highly recommend

this step as it can not hurt. The glue will also allow you to manipulate

the wire without having to worry about breaking the connection or worse yet,

break the USB connection to the camera board.

Then, carefully reinstall

the memory board by aligning the pins/socket and gently press it into place

(press on the foam piece attached to the top of the memory board. Be careful not

to pinch the wires you connected. You should lead the wires out from under

the memory board, towards the location where the R/C switch circuit will be located (left side

of lens, just below the shutter switch)

Feed these wires through the middle case section as you reinstall

it, being careful not to pinch the wires. Be sure to properly reinstall

the silver plastic shutter button if it had fallen out during disassembly.

It simply fits into two pivot guides located on the middle case section.

Check its operation before continuing. Reinstall the

two tiny screws,

attaching the middle case section to the bottom case section.

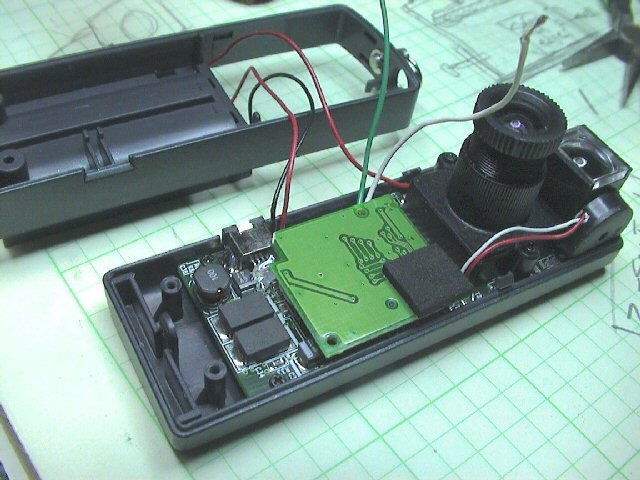

This picture is taken from another angle so that you can see

where the wires need to exit.

All we need to do now is assemble the circuit that will connect

to these three wires.

Take a break,... you are half way there!

The

first step in building the circuit is to bend all the IC leads in toward the IC and snip off all the

long IC leads. Then using thin non-insulated wire (I used the leads I cut

off of components such as resistors and capacitors),

make the connections shown in "red".

The connections you need to make first are the ground connections that consist

of pins 6, 7, 8, and 10. I make these using one piece of wire. Then

make the connection connecting pins 5 and 14 (+V). After making these

connections, use thin insulated wire to make the "green" connections, connecting

pins 2 & 11, and pins 3 and 9 respectively. After this, connect the

resistor between pins 1 & 4, and then connect the capacitor between pins 4 & 7.

When adding these components, orient them such that they are right along side

the IC (see picture below). When

soldering to the IC, be sure to use minimal amount of heat else you will ruin

the IC. It is also probably best to tin each IC pin first before making

any connections. If at all possible, try to use a small clip-on heat sink

when soldering to the IC too (a simply clip-on alligator clip should suffice).

Take your time... have lots of patience. It is also very handy to have a

helping hand, such as another person of a mini bench-top holder/vise.

NOTE: It has been determined that in order to have

the camera properly operate with either batteries inserted or when connected to

your computer via the USB cable (i.e. not connected to your receiver), there must be a resistor placed across the servo

input lead and ground (between pins 8 & 9 on the IC). I used a small 100K SMD resistor and soldered it across the IC's pins, right along side the IC,

similar to the other resistor and capacitor. With out this pull-down, the

IC's pin will be allowed to float, occasionally triggering the camera's shutter, sometimes even causing the camera to lock up. I have had a few successes

with out the resistor but to be honest, you are better off adding it!

The

first step in building the circuit is to bend all the IC leads in toward the IC and snip off all the

long IC leads. Then using thin non-insulated wire (I used the leads I cut

off of components such as resistors and capacitors),

make the connections shown in "red".

The connections you need to make first are the ground connections that consist

of pins 6, 7, 8, and 10. I make these using one piece of wire. Then

make the connection connecting pins 5 and 14 (+V). After making these

connections, use thin insulated wire to make the "green" connections, connecting

pins 2 & 11, and pins 3 and 9 respectively. After this, connect the

resistor between pins 1 & 4, and then connect the capacitor between pins 4 & 7.

When adding these components, orient them such that they are right along side

the IC (see picture below). When

soldering to the IC, be sure to use minimal amount of heat else you will ruin

the IC. It is also probably best to tin each IC pin first before making

any connections. If at all possible, try to use a small clip-on heat sink

when soldering to the IC too (a simply clip-on alligator clip should suffice).

Take your time... have lots of patience. It is also very handy to have a

helping hand, such as another person of a mini bench-top holder/vise.

NOTE: It has been determined that in order to have

the camera properly operate with either batteries inserted or when connected to

your computer via the USB cable (i.e. not connected to your receiver), there must be a resistor placed across the servo

input lead and ground (between pins 8 & 9 on the IC). I used a small 100K SMD resistor and soldered it across the IC's pins, right along side the IC,

similar to the other resistor and capacitor. With out this pull-down, the

IC's pin will be allowed to float, occasionally triggering the camera's shutter, sometimes even causing the camera to lock up. I have had a few successes

with out the resistor but to be honest, you are better off adding it!

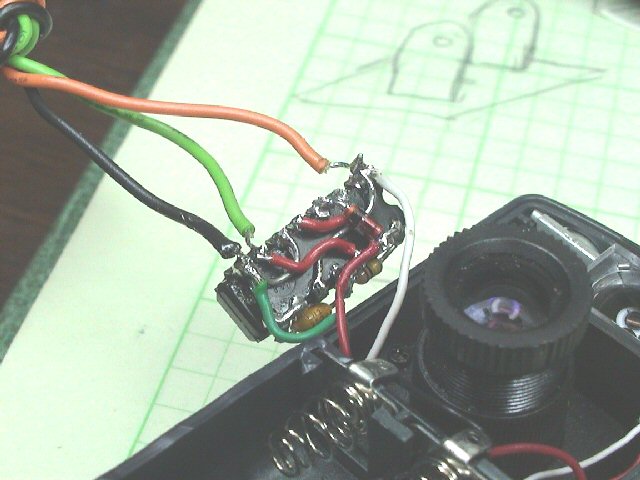

When completed, your R/C switch circuit should look like that of the

picture to the left. It might

look crude but if properly built, it should be fairly compact, just small enough

to easily fit in the Aiptek case.

At this stage if you want, you could hook up some temporary wires

and test the circuit. If this is your first R/C switch you built, it is

probably not a bad idea to test prior to continuing, just to have confidence

that it is wired correctly (and also to be certain the IC is still good!)

Here's another picture of the finished circuit (top

view).

Notice how snug both the resistor and capacitor are to the IC.

The capacitor pictured here is a small .022uF tantalum type capacitor; you could

also use a disc type but I believe they will be slightly larger in size.

I then cut a piece of thin

white cardboard such that it neatly fit inside the location where the R/C

switch circuit will reside. This acts as an insulator, protecting the R/C

switch circuit

against shorts.

The R/C switch circuit is then

wired up appropriately, connecting the shutter wire (red wire) to the other

end of the diode, connecting the USB power wire (white wire) to pin #14, and

finally connecting the ground wire (green wire) to pin #8. (Granted, I

should had used red for +V, Green for ground and white for shutter switch... Oh

well, I already had them soldered to the camera board before I noticed this.. :(

)

I then connected a temporary servo wire to the circuit and

tested to be certain it was working properly (see black green and orange

wires in picture).

Here's another picture

showing where the R/C switch circuit is located in the camera. There's ample room

along the left side the lens, just below the shutter switch.

The permanent servo wire was then connected to the R/C switch

circuit (similar to

the servo wire used for testing as indicated above). I then

oriented the R/C switch circuit in its place

and applied a few drops of hot melt glue to hold it in place. The servo

wire will exit out of the opposite side of the camera case as shown in the

picture.

Using a razor blade, I then

notched out a small opening in the middle case section. After this, I

reinstalled the top case section. Before installing, be sure to adjust the

silver plastic focus ring so that it is fully clockwise (focus set to infinity).

This will insure that the focus setting is correct.

Reinstall the last remaining

screw, the screw you had first removed during disassembly which is located

under the battery door. Also, be certain the sliding battery compartment door is

properly in place before snapping the top case onto the camera.

YOU ARE NOW DONE!

Here's a picture of the

completed modification.

Now it's time to test !!

Testing and Operation Instructions...

1) Turn on your transmitter

2) Plug the camera's servo connection into a channel on your receiver (I usually

use the throttle channel, Ch#3, for testing)

3) Connect a battery to the receiver. Upon connecting your receiver

battery, your camera should also power up, as indicated by a "beep".

4) If the throttle lever is set low and you do not hear any more beeps from the

camera, try toggling the throttle level (go from low to high, then back low).

If your circuit is working properly, you should here a "beep" from the camera,

indicating that it had taken a picture. Test a few times to be sure all is

working fine.

5) If after applying receiver power you hear the camera continually beeping, it

is indicating that the throttle position is causing the shutter switch to be

continually "On". Try alternating the throttle lever position (low to

high) and see if the camera beeping stops. If is does, you should be able

to toggle the throttle lever (high to low, then back to high) and hear the

camera beep once, indicating it had taken a picture.

Like most Aiptek cameras (and other small, cheap digital camera),

you need to pause approximately 4-5 seconds between taking pictures (the camera

needs time to save the picture to memory). If you do not pause enough time, you

will hear the camera beep fast, indicating a problem. Wait a few seconds

between taking pictures and you'll be OK.

Additional Notes...

There has been rare occurrences where an Aiptek camera can simply go

"berserk"...., i.e. continual beeping or just does not work at all (indicated

some times by all "eights" (888) in the camera display). In this case, it

is good to reset the camera by hold the "mode" button down

for a few seconds (until a beep is heard) while the camera is powered up. Removing

power and reapplying has some times fix the problem too.

If you do not like how the circuit operates (i.e. you would like

to reverse the operation such that the camera is triggered inversely in regards

to the control channel), you can either reverse the channel via your transmitter

(if it has that ability) or you can simply move the diode from pin #13 to pin

#12 (or vice-versa) on the R/C switch circuit. Either should work to your

satisfaction. You can also replace the 100K resistor to alter the R/C

switch operation in respect to a particular servo pulse/position. The 100K

resistor sets the position to be approximately 1/2 of the servo's throw position

(~1.5ms)

I have also noticed that when testing this setup with a 6 volt

receiver battery, the camera usually does not power up properly. If you

therefore plan to use a 5 cell receiver battery pack, you should also include a

5v voltage regulator in the design. I have built a few of these using a

surface-mount 8-pin (DIP) voltage

regulator.

Additionally, this modification

also allows you to use the camera as it was originally intended to be used.

You can simply unplug it from your receiver, throw 2 "AA" batteries in the

battery compartment and take picture using the original shutter button.

You can simply wrap the servo wire around the camera and put an elastic band

around it to keep it out of your way. How neat is that ???

I have also hacked many of these camera, completely removing the

case (saving weight) and wrapping the whole assembly (camera board and R/C

switch circuit) in heat shrink wrap. This makes for an even smaller and

lighter package (granted, you will then not be able to use it with batteries).

Click here to see a sample.

Good luck and hope this webpage was helpful!...

NEW PCB STUFF.... UNDER CONSTRUCTION

NEW PCB STUFF.... UNDER CONSTRUCTION

Here's

a new project that includes the designing of a PCB for the DIP circuit shown

above. Click on the links below to see more pictures. More to come

soon...

Here's

a new project that includes the designing of a PCB for the DIP circuit shown

above. Click on the links below to see more pictures. More to come

soon...

PCB

PCB#0

PCB#1

PCB#2

PCB#3

PCB#4

PCB#5

PCB#6

PCB#7

PCB#8

Here's

a newer (?) project that includes the designing of a PCB for a Surface

Mount Device (SMD) version of the circuit shown above. Click on the links

below to see more pictures. More to come soon...

Here's

a newer (?) project that includes the designing of a PCB for a Surface

Mount Device (SMD) version of the circuit shown above. Click on the links

below to see more pictures. More to come soon...

SMD#1

SMD#2

SMD#3

SMD#4

SMD#5

SMD#6

SMD#7

SMD#8

SMD#9

SMD#10

SMD#11

SMD#12

SMD#13

And even with my failing eyesight,.. it actually works !

Earthmen

Productions

© Dec-00-Mar-12